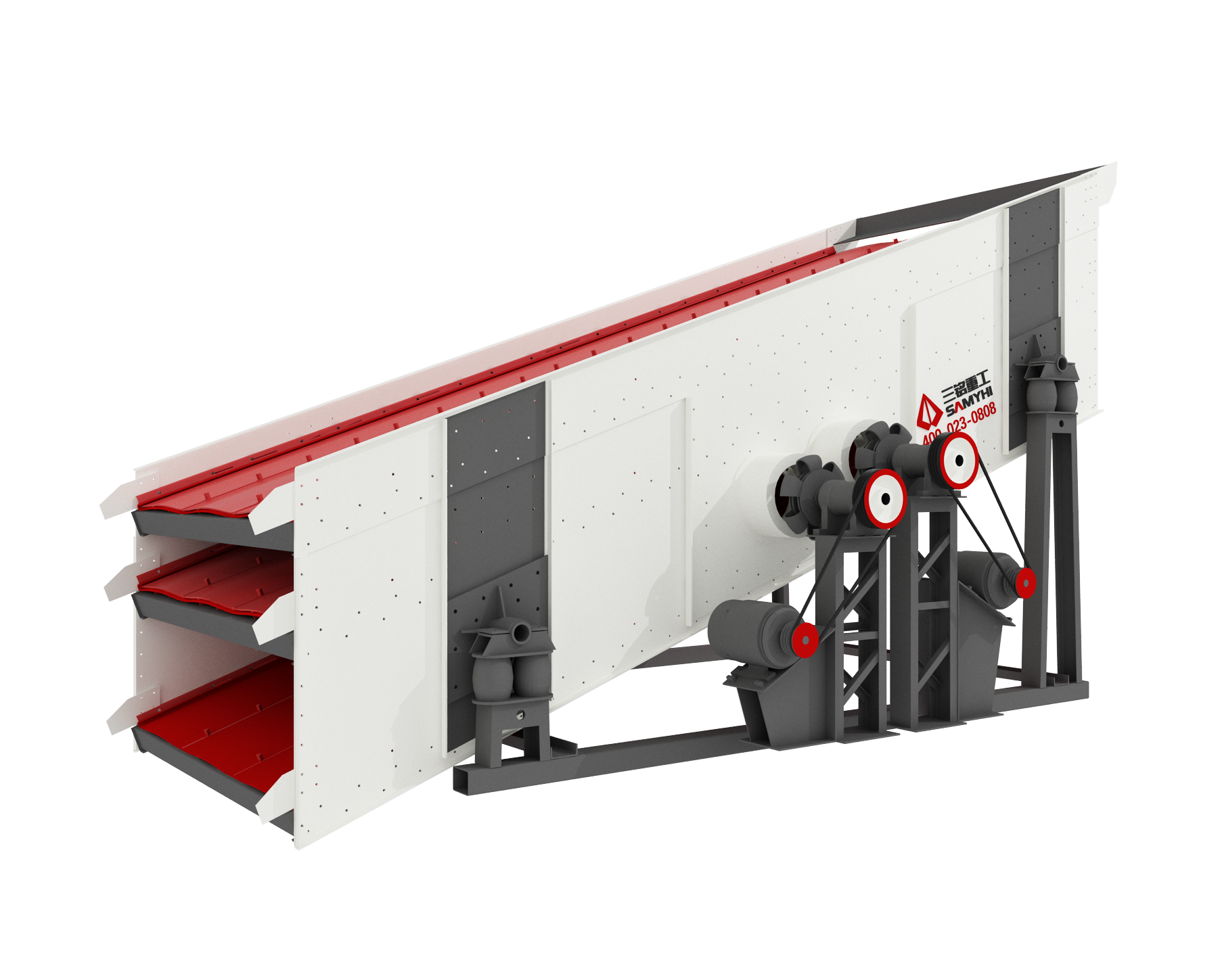

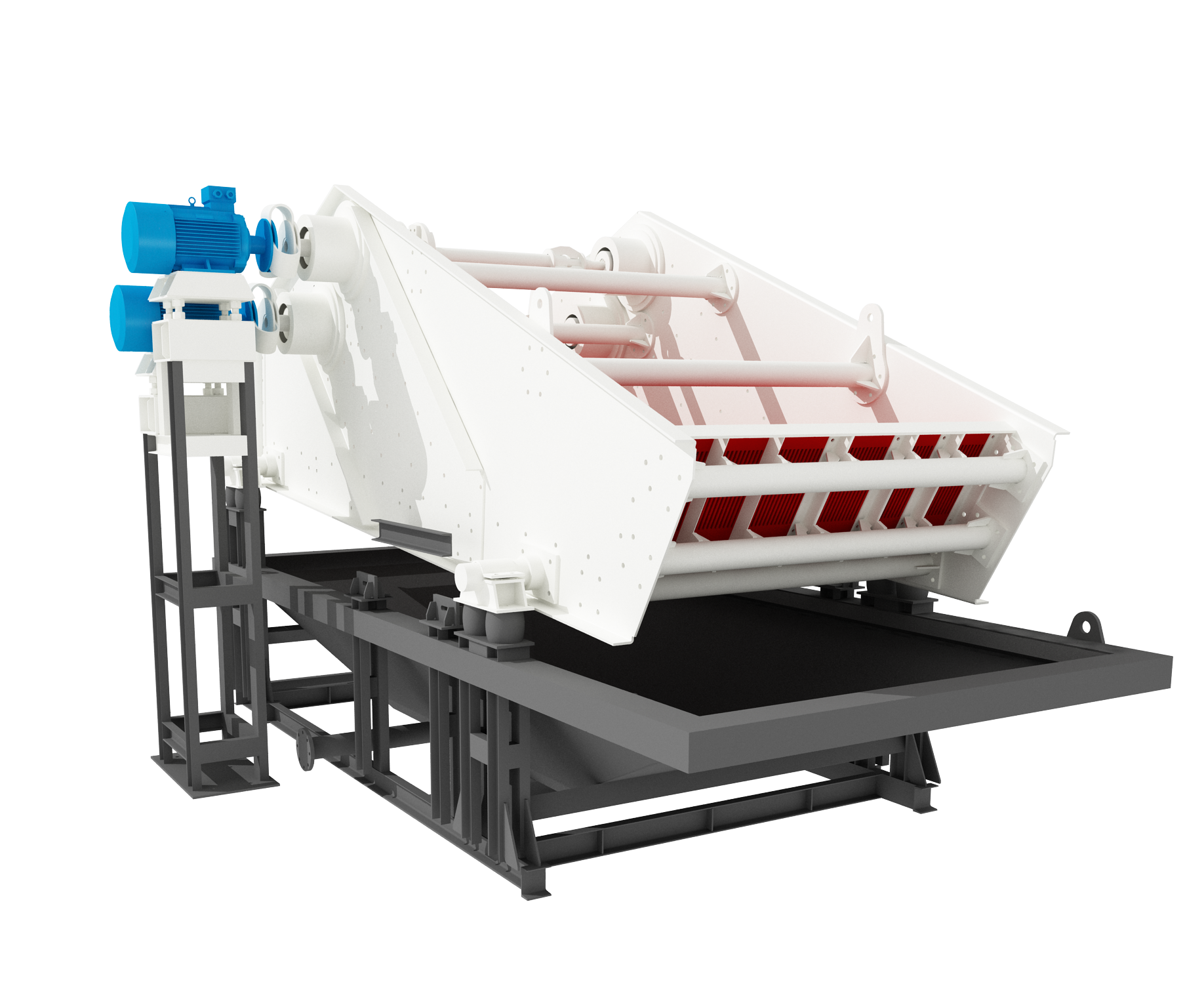

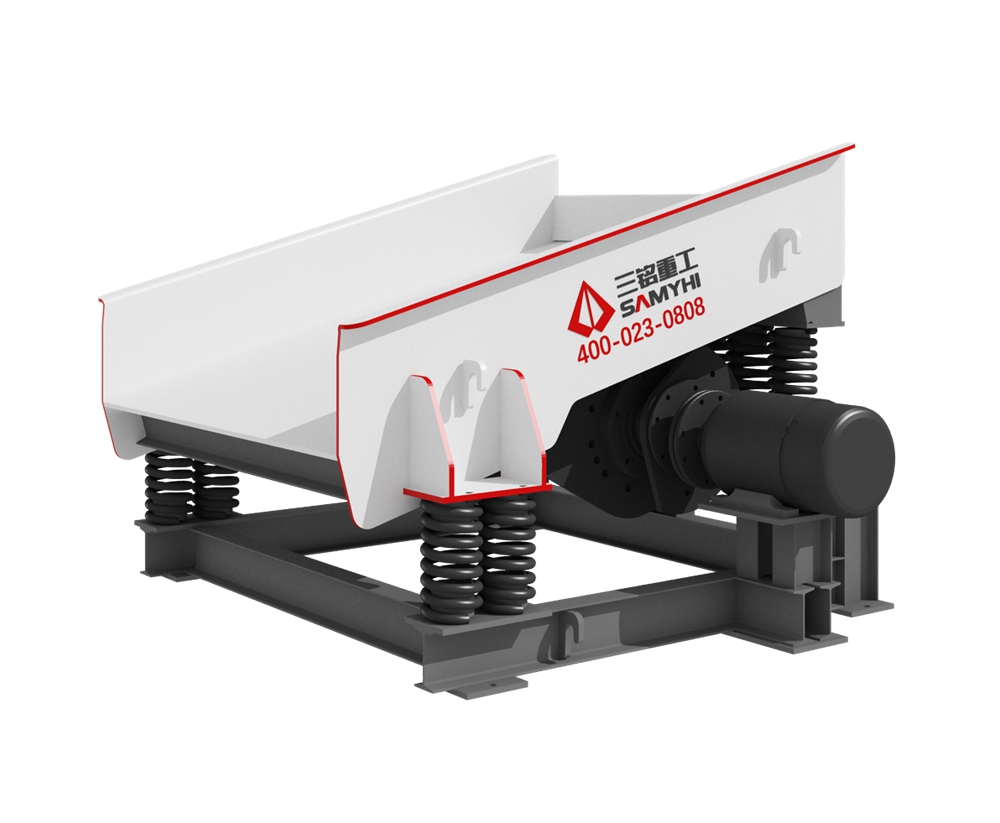

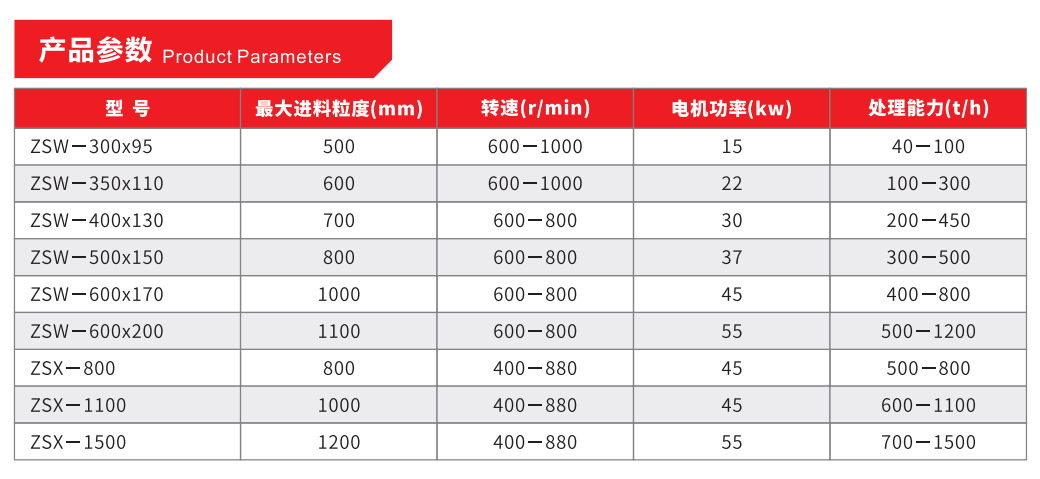

Feeding granularity: ≤1200mm

Production capacity: 40-1200t / h

Adapt to materials:

River pebbles, granite, basalt, quartz stone, iron ore, diabase, limestone, calcite, dolomite, barite, talc, gypsum, bentonite, etc.

Application areas:

It is widely used in mining, metallurgy, coal and other industries. It is suitable for uniformly and quantitatively feeding bulk and granular materials from storage bins or other storage equipment to receiving equipment.

- Introduction

- parameters

This series of double-shaft vibrating feeder is a long-term research and development company, which combines the advantages of similar products and repeatedly summarizes and improves in practice to produce excellent performance feeding equipment. It is widely used in mining, metallurgy, coal and other industries. It is suitable for uniformly and quantitatively feeding bulk and granular materials from storage bins or other storage equipment to receiving equipment.

1. The cascade bar drop is large, and the bar is designed into the size of the head structure, not easy to block material, fast cutting, specific good pre-screening effect;

2. Adopt frequency conversion controller to adjust the frequency, which is convenient to control the constant feed quantity of coarse crushing crusher;

3. The leaking mud part of the feeding tank can be adjusted and made according to the needs of customers, and even the leaking mud and non-leaking mud can be completely exchanged;

4. The exciting force is very strong, the transmission part of the main shaft with large eccentricity, and the two eccentric shaft eccentricity through Angle adjustment to form the best. Resultant force, to achieve the best feeding effect;

5. The transmission part adopts the thin oil inner circulation lubrication structure, which makes the lubrication environment of the bearing good and prolongs the service life. There are exhaust holes and oil quantity observation holes on the oil tank to ensure that the temperature of the lubricating oil is not too high and there is no shortage of oil at any time.

6. The feeding box adopts low alloy special material, and the design of complete riveting structure, can bear more load and not easy to deformation, fracture and other hazards;

7. Stable vibration, reliable operation, long life, low noise, small power consumption, convenient maintenance.

.jpg)